VMC Machining in Chennai

VMC Machining in Chennai

NATHAN TECHNOLOGIES provides a sheet metal VMC Machining in Chennai using the latest in metal folding technology for the production shape required.

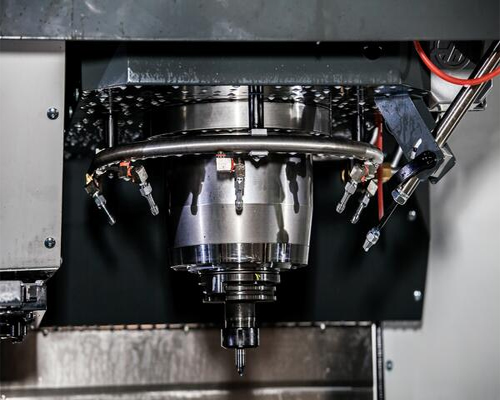

VMC machining refers to machining operations that operate vertical machining centers (VMC), which, as the name suggests, have perpendicularly oriented machine tools. These machines are mostly utilized to turn raw blocks of metal, such as steel or aluminum, into machined components.

VMC can be equipped with several adjustments. For example, there are several angles of approach available as well as rotary and other positioning devices upon the worktable. A later depiction of the VMC design added power and hydraulic feeding devices to make the system more automated and, ultimately, computerized controls were added to allow for more automation in operation, repeatability, tool selection, and contour control.

Advantages of VMC Machining

- The simple structure of VMC makes it easy to fasten the work piece in the necessary position.

- Gravity works with the VMC design. Coolant sprayed at the top of the machine tool and work piece trickles down to cover the rest of the target.

- VMC have an extensive field of vision, enabling operators to study the operations and, if needed, make modifications to resolve any issues.

- The perpendicular design takes up less floor space than a flat design.

- VMC can produce complex shapes and structures with a high degree of accuracy.

Applications of VMC Machining

VMC can be used to make parts and products for a broad range of industries and applications. Though, they are mainly used for high-precision, high-accuracy, and production projects, including those involving the following machined components:

Complex curved parts: Examples of parts with complex curves include impellers, cams, and propellers. Though these parts are difficult to manufacture with precision and accuracy using the conventional machining process, a multi-axis VMC with CNC technology can produce them easily and quickly.

Special shaped parts: Examples of parts with irregular or special shapes include brackets and bases. This mechanism often has highly complex designs, which are hard to produce using other manufacturing processes but easy to produce using VMCs with automatic machining capabilities.

Military parts: The military industry is subjected to a mixture of standards that dictate how a part can be designed and built. The accuracy and precision of VMCs ensure the machined components produced fully meet the necessary application and industry specifications.

Visit us in Google Maps

Leave a Reply

Want to join the discussion?Feel free to contribute!